Turbo Underboost Fault: Land Rover Discovery

Mr H called Fitch Autos in Brownhills with symptoms he couldn’t make sense of.

His Land Rover Discovery Sport drove normally around town, but when climbing the longer inclines toward Cannock and Aldridge, the engine’s power dropped away. The vehicle hesitated, and a restricted performance warning message appeared before clearing as soon as the road levelled.

Some days, the issue didn’t show. Other days, it was obvious something wasn’t right.

It didn’t take long for him to feel concerned about relying on the vehicle, especially on the steeper routes around Walsall and Burntwood.

He needed to know what was behind the reduced power, and he needed a team that could turn those worrying symptoms into an evidence-led diagnosis.

The next step was clear: the vehicle needed a thorough assessment, so we booked it in without delay.

Investigating the First Clues of a Turbo Underboost Fault

Now that Mr H’s Land Rover Discovery Sport was with Fitch Autos in Brownhills, the diagnostic process could begin. Our first task was to understand how the symptoms appeared for him on the road. We spoke with him about when the reduced power first showed up, how the engine responded on the climbs toward Cannock and Aldridge, and whether the restricted performance warning message stayed on or cleared once the road flattened out. Information like this helps define the conditions we need to replicate during testing.

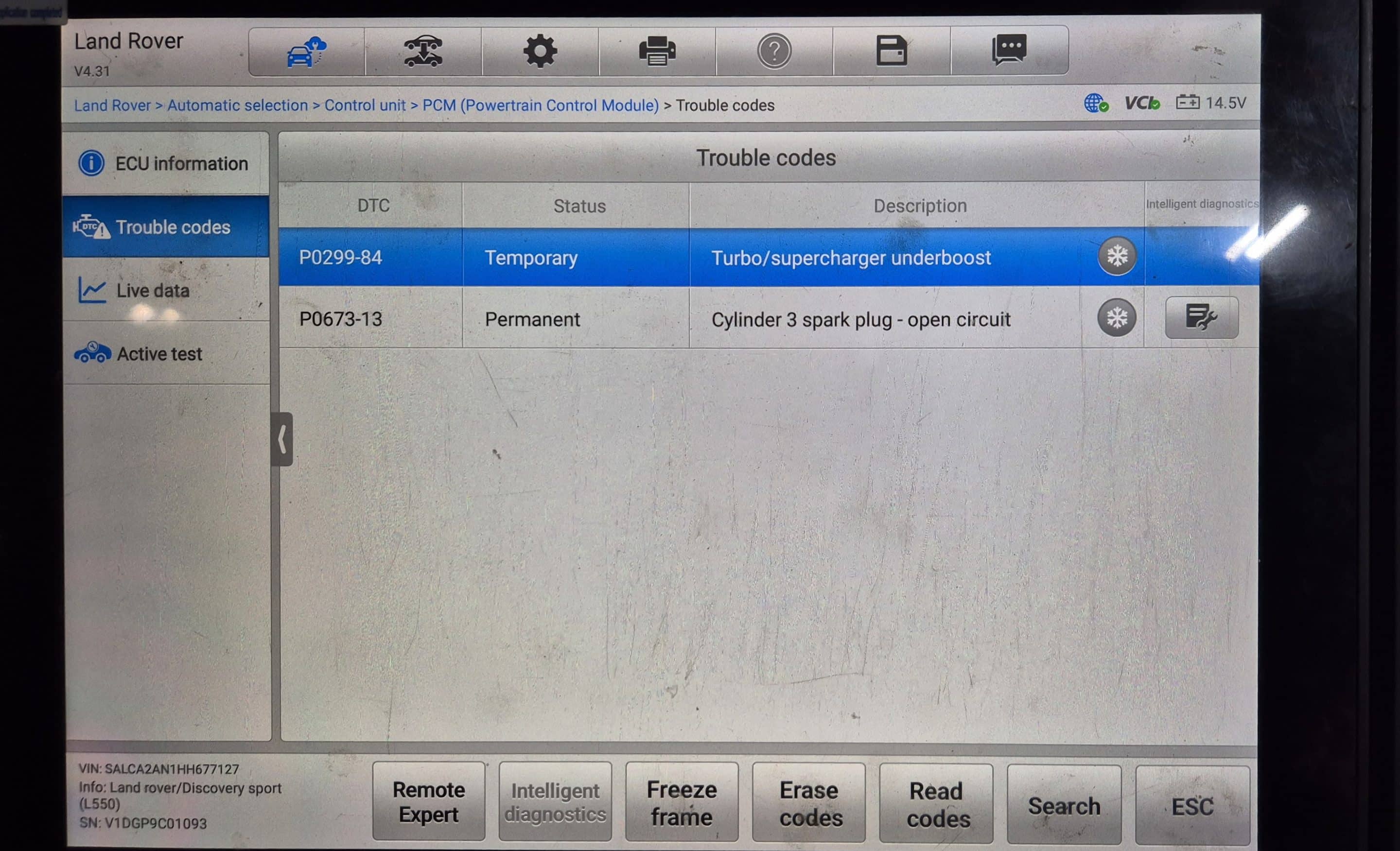

With these details confirmed, we connected the vehicle to our manufacturer-standard diagnostic tool and accessed the appropriate Land Rover technical information to guide the evaluation. The initial scan produced a single stored code:

P0299-84 – Turbo/Supercharger Underboost

The turbocharger wasn’t producing the boost pressure the engine control module was commanding.

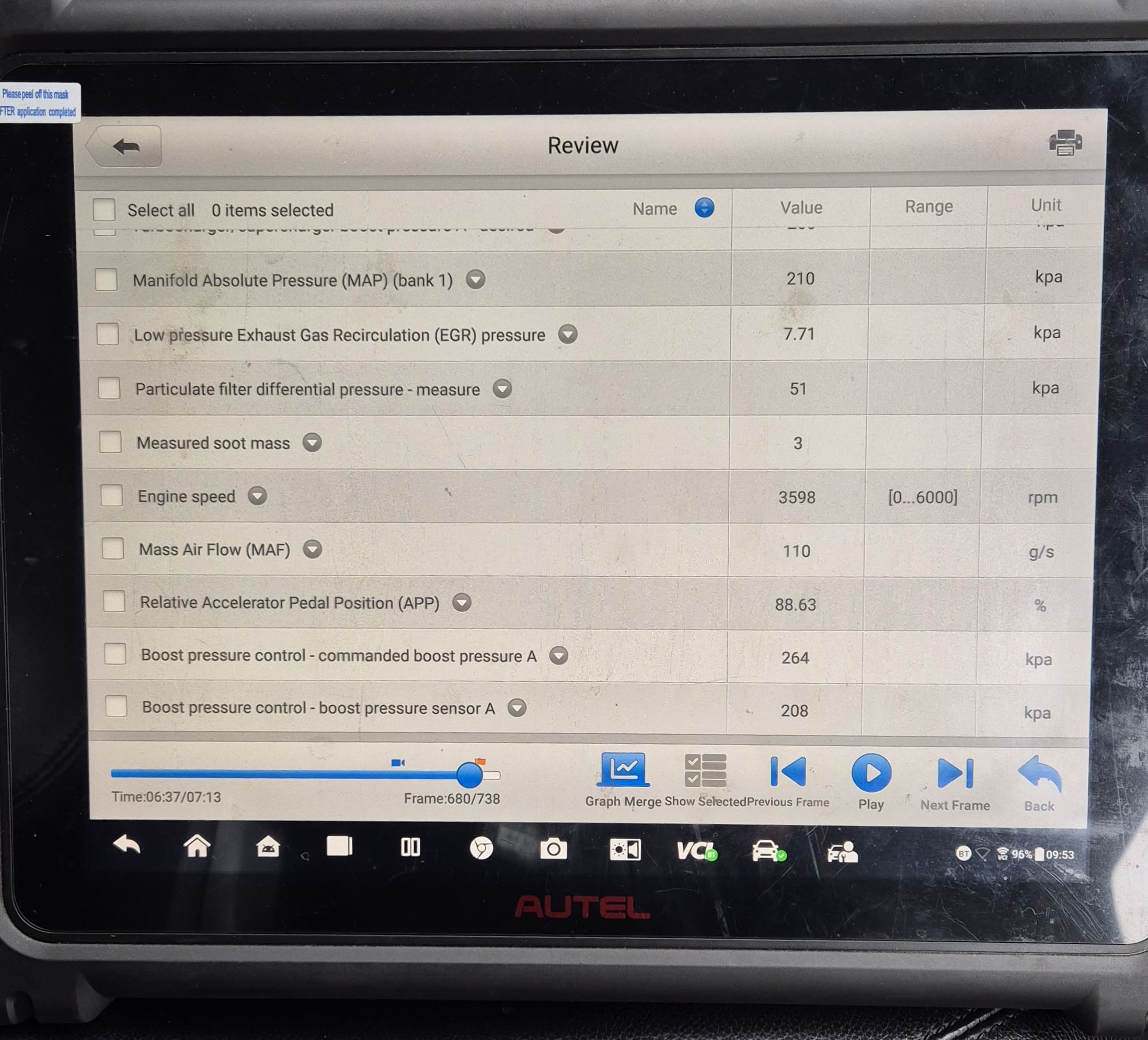

To see how the Discovery Sport performed under similar load, we carried out a controlled road test along routes where gradients matched the conditions Mr H described. We logged serial data throughout the drive to monitor how the engine responded. The fault reappeared exactly as he had experienced it, allowing us to return to the workshop with a full data record.

The data was consistent: commanded boost pressure and actual boost pressure did not match. The engine control module was demanding more boost than the turbocharger could achieve, and under load, the system consistently fell short. This pattern aligned with the restricted performance warning message that appeared on the steeper sections of Mr H’s journeys around Walsall and Burntwood.

Although this confirmed a genuine boost pressure imbalance, it did not reveal the underlying cause. A leak, a faulty sensor signal, a control issue with the actuator, or a mechanical problem inside the turbocharger could all be the culprits. To determine the exact reason for the underboost, we moved on to a structured diagnostic evaluation.

In-Depth Checks to Locate the Turbo Underboost Fault

With a clear shortfall between commanded and actual boost pressure, the next stage was to identify what was preventing the Land Rover from achieving the level the engine control module required. Each potential cause had to be examined in order, ruling out system components one at a time.

These are the steps we took:

Step 1: Inspecting the Intake and Charge-Air System

- We carried out a detailed inspection of the intake pipework, intercooler connections and associated hoses, looking for splits, loose fittings or signs of disturbance.

- Everything appeared secure and undamaged, so the intake and charge-air system were ruled out as contributing to the turbo underboost fault.

Step 2: Verifying System Integrity with a Pressurised Leak Test

- Using pressurised leak detection equipment, we introduced smoke into the system to confirm whether any boost pressure was escaping under load.

- The system held pressure without any signs of leakage, allowing us to eliminate pipework faults and intercooler leaks.

Step 3: Testing the Boost Pressure Sensor and Wiring

- We checked the boost pressure sensor using an oscilloscope and circuit load testing equipment to confirm accurate supply, ground and signal integrity.

- The readings were all within expected values, meaning the sensor and its wiring were not responsible for the boost pressure mismatch.

Step 4: Evaluating the Turbocharger Control Actuator

- We assessed the turbocharger’s actuator to ensure it was responding correctly to the control signals sent by the engine control module.

- Oscilloscope traces showed a correct response, and the wiring passed all checks, ruling out any actuator-related issue.

Step 5: Mechanical Inspection of the Turbocharger

With leaks, sensors and control components eliminated, attention turned to the turbocharger itself. A mechanical inspection provided the conclusive answer: the turbocharger itself had failed and could no longer generate the commanded boost pressure when the engine demanded it.

This matched what the serial data showed us during the initial investigation, leaving no doubt that internal turbocharger failure was the root cause of the turbo underboost fault.

Fitting the New Turbocharger

Once we had confirmed the turbocharger had failed internally, we contacted Mr H to explain exactly what the testing had shown. We talked him through the structured diagnostic process, how each area of the system had been ruled out, and why the turbocharger itself was responsible for the turbo underboost fault. With his approval to move forward, we began the replacement work.

Here’s what we carried out:

Turbocharger removal and preparation

- Removed the necessary intake pipework, heat shields and surrounding components to gain clear access to the turbocharger.

- Inspected the turbocharger’s oil feed and return lines for any signs of restriction or contamination that could affect the new unit.

Fitting the replacement turbocharger

- Removed the failed turbocharger and prepared the mounting surfaces to ensure a clean and correct fit.

- Primed the lubrication system so the replacement turbocharger received oil immediately during initial start-up.

- Installed an OEM-spec replacement turbocharger using the correct seals, gaskets and torque settings specified for this engine.

Reassembly and essential checks

- Reassembled the intake system and related components, confirming all brackets, fixings and fittings were correctly secured.

- Verified oil supply to the new turbocharger and checked the area for any air, oil or exhaust leaks following installation.

- Confirmed that all electrical connectors and vacuum or pressure hoses were correctly reinstalled.

- Cleared the stored fault code and prepared the vehicle for a controlled test drive.

Final validation

- Performed a structured road test with serial data logging to assess how the turbocharger responded under load.

- The replacement unit reached the commanded boost pressure consistently across the relevant operating range.

- The restricted performance warning message did not return, and no additional faults were recorded during the assessment.

During the repair, Mr H remained mobile using one of our courtesy cars, helping to minimise any disruption while the work was carried out.

The Result: A Resolution for the Land Rover

With the replacement work completed and all checks passed, the Land Rover was taken out for its final assessment. On the test route, the engine delivered consistent power again, with no hesitation on the climbs around Brownhills and Cannock. The restricted performance warning message did not reappear, and the vehicle responded cleanly throughout the drive.

Back at the workshop, we reviewed the serial data captured after the repair and compared it with the information logged earlier in the process. The gap between commanded and actual boost pressure had been eliminated, confirming that the turbocharger was now reaching the level the engine control module required.

The results left no doubt: the internal failure had been addressed, and the Discovery Sport was fixed.

The Independent Land Rover Specialists Drivers Rely On

If your Land Rover is losing power, displaying warning messages or hesitating under load, it needs to be assessed by a team who understand these vehicles in depth. Faults like the turbo underboost issue on Mr H’s Land Rover Discovery Sport can become more noticeable on the gradients around Brownhills, Walsall and Cannock.

At Fitch Autos, we combine specialist diagnostic tools with Land Rover technical information to identify faults accurately. Whether you’re dealing with reduced performance, a warning message or a more complex issue, our technicians are equipped to help.

By choosing us, you benefit from:

- Diagnostic capability using manufacturer-level equipment

- Access to Land Rover technical data and guided test plans

- Evidence-led fault tracing carried out by experienced technicians

- Clear communication throughout the diagnostic and repair process

- A 12-month parts and labour guarantee

- Courtesy car available to keep you mobile during repairs

Join the {{review-count}} drivers who rate us {{average-rating}} stars on Google and trust our team with their Land Rovers every day.

If your Land Rover is showing similar symptoms, contact us today on 01543 452630 and we’ll arrange a booking for a full diagnostic assessment.