BMW Charging Fault

“Your electrical machine electronics (EME) unit has failed beyond repair. It must be replaced and it’ll cost you just over £9,500.”

That was the crushing news Mrs B received from her BMW dealership when she sought help with her 2020 BMW 5 Series 530e Plug-In Hybrid. For any driver, hearing a figure like that is enough to make your stomach sink.

On top of the looming repair bill, the situation was already severe. Heating and air conditioning had failed, and the charging system could no longer replenish the high-voltage battery. Piece by piece, the BMW was edging closer to the point of being unusable.

Instead of giving in to the dealer’s costly assessment, Mrs B turned to Fitch Autos in Brownhills. For our specialists, this wasn’t the final chapter — it was the start of a complex challenge we were more than ready to take on.

Read on to discover how our BMW experts carried out a precise EME repair that brought Mrs B’s BMW back to life… without the crippling cost of full replacement.

Tracing the BMW Charging Fault from the Start

Our process began with a thorough discussion with Mrs B, allowing us to build a clear picture of how the issues had unfolded, which symptoms had appeared first, and what steps had already been taken. This stage was essential, ensuring we understood the full context instead of assessing the BMW in isolation.

With that background in place, we connected our dealer-level diagnostic equipment to the vehicle and retrieved the stored fault codes. Several appeared, including:

- 21E720 – Charging electronics fault: The link between the charging system and its controller was missing, preventing the car from charging.

- 80120E – Electric A/C compressor undervoltage/overvoltage: The compressor shut down because voltage levels were outside the correct range.

- 8011C4 – A/C compressor voltage sensor fault: The compressor’s internal sensor was sending inaccurate signals about the high-voltage supply.

- 030ECD / 030EC1 – Charging management errors: The car’s charging process could not be managed safely.

Together, these codes revealed a clear pattern: key high-voltage systems — including the charging function, the PTC heater, and the climate control — were all being affected.

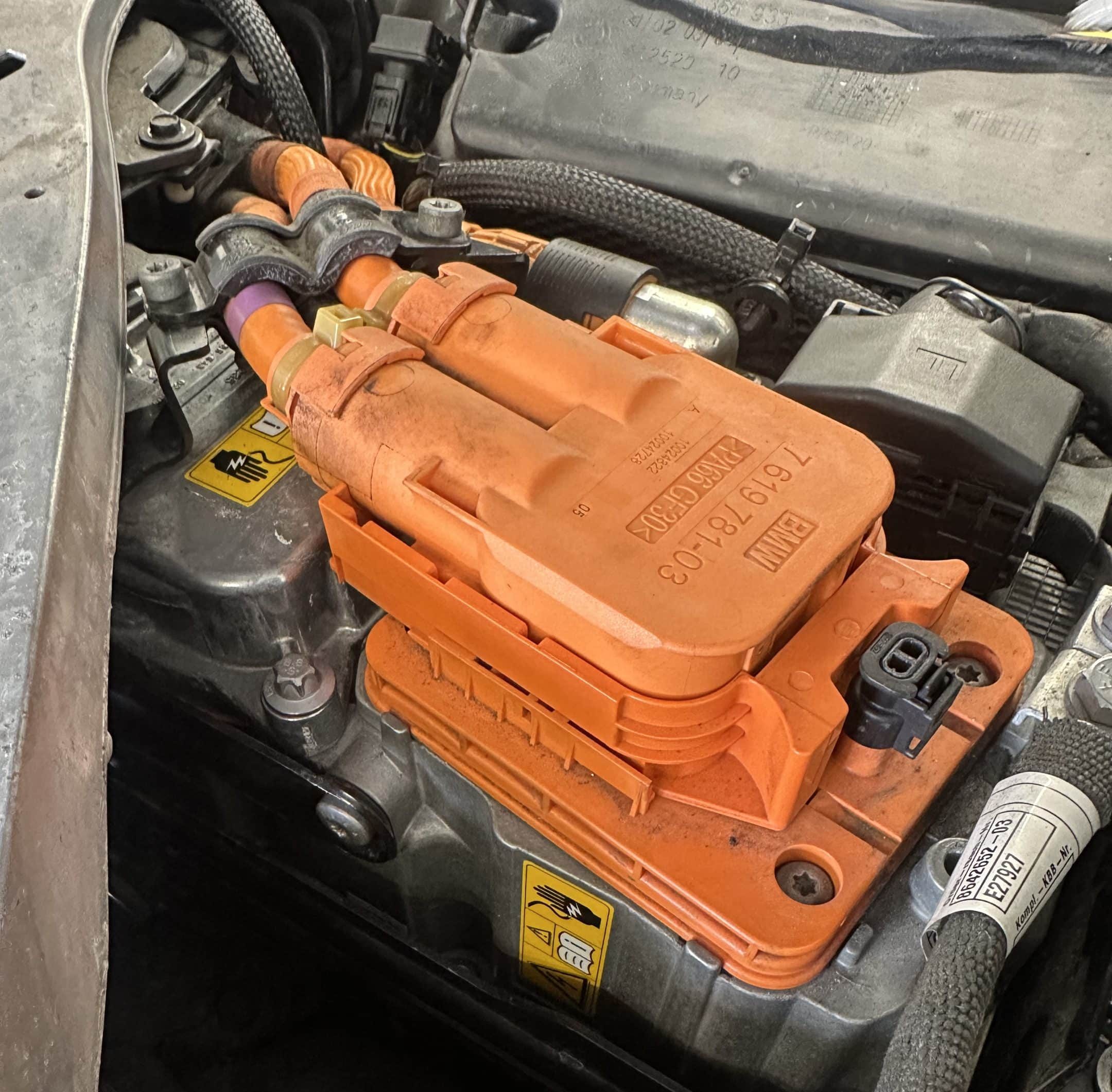

All of these systems were linked through the electrical machine electronics (EME) unit, the very component the dealer had already eyed up for replacement. For us, this wasn’t ‘case closed’, but a strong clue pointing to a central issue in the vehicle’s high-voltage distribution.

It was clear that a deeper investigation would be the essential next step.

How the BMW Heater Fault Linked to Other Failures

Using Wiring Diagrams

The next stage of our investigation involved tracing the high-voltage supply routes. Since the fault codes all pointed in that direction, we consulted BMW’s detailed wiring diagrams. These provided the clarity we needed, setting out how each part of the system should receive power supply under normal operation. By treating the diagrams as a roadmap, we could see exactly where the voltage supply was breaking down.

Checking the Evidence

When we reviewed serial data from the high-voltage components, it became clear that the A/C compressor wasn’t receiving any voltage at all. This showed that the compressor itself wasn’t at fault. The real issue was that no supply was leaving the EME. The diagrams also confirmed that the charging electronics, the PTC heater, and the air conditioning system were all dependent on that same circuit, protected internally by a fuse inside the EME.

Applying Our Own Test Plans

To take the diagnosis further, we used custom high-voltage test plans developed in-house for hybrid and electric vehicles. Handling these systems is never without risk, which is why only qualified and certified technicians can safely carry out the work. These plans allowed us to evaluate each component under controlled conditions and confirm whether it was operating as intended.

Digging Into the EME

Where the main dealer’s solution was to replace the complete EME, our approach was to strip the unit down and test it at component level. Inside, we uncovered the problem: the high-voltage fuse had blown. A fuse doesn’t usually blow without cause. In many cases, it happens because another part of the circuit draws too much current, forcing the fuse to sacrifice itself to protect the rest of the system.

Isolating the Culprit

To identify the root cause, we methodically tested every part of the affected circuit — from wiring harnesses and the A/C compressor to the onboard charger and finally the PTC heater. It was the heater that produced abnormal readings. Its resistance was far too low, meaning it was drawing excessive current and had overloaded the fuse. Using precise calculations, we confirmed this as the cause beyond doubt.

Taken together, these findings showed that the true fault lay not in the entire EME, but in a single blown fuse triggered by the failed PTC heater. This gave us the clarity to repair specific components rather than resorting to a full replacement.

Repairing the EME and Restoring the High-Voltage Circuit

With the root cause identified, the focus shifted to carrying out the necessary repairs:

- Sourcing the fuse: The required high-voltage fuse wasn’t available separately from BMW. Using our specialist supply network, we sourced one to the correct specification. The EME was stripped down, the replacement fitted precisely to manufacturer standards, and the unit was carefully reassembled.

- Replacing the PTC heater: The defective heater was removed and replaced with a high-quality unit, ensuring the high-voltage circuit could once again operate safely.

- Final system checks: We then re-tested the circuit using specialist tools, including an insulation resistance tester and a multimeter. The results confirmed that the repaired EME and new heater restored the high-voltage feed, and that the system was now performing safely within specification.

The Results for Mrs B and Her BMW

With the repair complete, the change was immediate. A BMW that had been edging closer to being unusable was suddenly dependable again, with heating, charging, and climate systems all operating as they should.

For Mrs B, the outcome was a major relief. Faced with a £9,500 dealer recommendation to replace the entire EME, she had been left worried about the future of her 5 Series. Our work showed that such an extreme step wasn’t necessary. The result wasn’t down to chance — it came from persistence, accurate testing, and the ability to apply specialist knowledge to high-voltage vehicle systems.

By combining our BMW expertise, qualifications to safely work on high-voltage vehicles, factory wiring diagrams, and in-house test plans, we were able to pinpoint the real fault and deliver a cost-effective repair at component level.

The outcome wasn’t just a fully operational BMW, but a driver who saved a significant sum and gained lasting confidence in choosing an independent specialist over a dealership.

Why Choose Fitch Autos for Your BMW Repairs

When faced with this complex BMW fault, our team applied every part of their expertise. Careful diagnosis, persistence in tracing the cause, and the ability to work at component level all came together to achieve the best result for Mrs B and her BMW.

That approach is what sets Fitch Autos in Brownhills apart. We don’t simply replace expensive parts; we find the root cause and deliver a solution that makes sense for both you and your vehicle.

Here’s what you can expect when you book with us:

- Fault evaluation that avoids unnecessary replacements

- Dealer-level diagnostic equipment and technical know-how

- Clear, honest advice you can trust

- High-quality repairs across all makes and models

- …All at a saving compared with dealer prices

We’re proud of what we deliver. We have a {{average-rating}} star Google rating from {{review-count}} satisfied customers.

Call Fitch Autos in Brownhills today on 01543 452630 — because your BMW deserves answers, not assumptions.